“Fatalities caused by falls from elevation continue to be a leading cause of death for constructions workers, accounting for 384 of the 991 construction fatalities recorded in 2016” –Bureau of Labor Statistics

With construction-related injuries and fatalities on the rise, it’s time to take a look at how your roofing safety protocols are being applied on the site.

What does OSHA say about roofing safety?

- OSHA regulation 501(b)(10)for Low-slope roofs, indicates that individuals performing “roofing work” can be protected by a combination of a warning-line system (such as Presco’s durable 4 mil pennant flags) as well as an additional fall-protection system to prevent falls. Some typical items used in conjunction with a warning line practice, include guardrails, safety nets, and PFA (Personal Fall Arrest) systems, such as a body belt are required. Since warning-line systems must be set up 6 feet from the edge of a roof, means there is a significant chance of injury outside of that designated area, however, when a roof is 50 feet or less in width, a safety-monitoring system alone is allowed without warning lines.

- OSHA regulation 501(b)(11) covers the safety guidelines for Steep-slope roofs, which state that workers with unprotected sides and edges 6 feet or more above a lower level, must be protected by either a guardrail system WITH toeboards, a safety-net system, OR a PFA system.

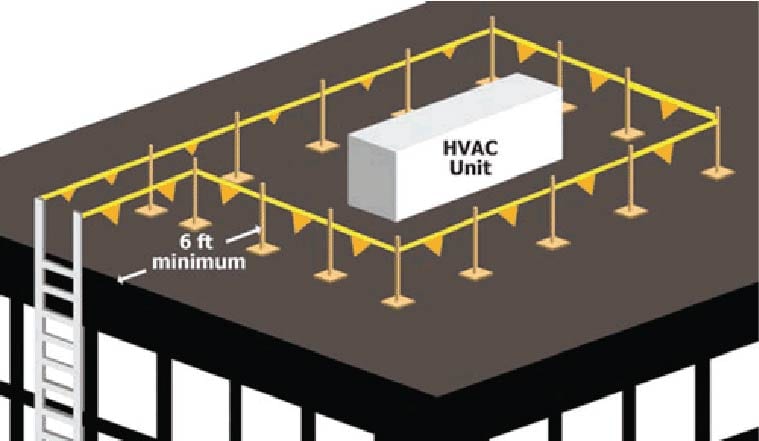

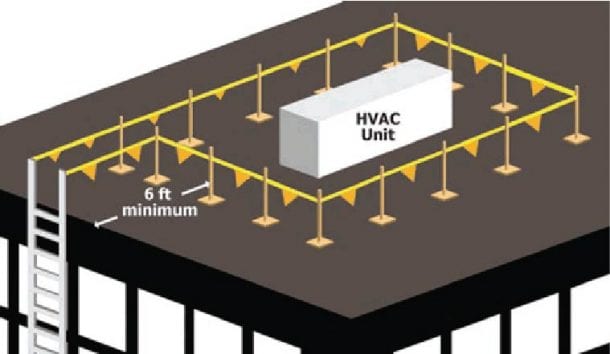

What does a Warning-line System Look Like?

Typical warning-line systems include ropes, wires, chains, pennant or banner lines and supporting stanchions.

How do I comply with OSHA’s Warning-line System Regulations?

The National Roofing Legal Resource Centeris an excellent resource for clarification of OSHA’s regulation 1926.502(f) regarding the proper usage of warning-line systems, and states the following guidelines should be taken into consideration when attempting to eliminate work-related roofing injuries:

- The warning line must be erected around all sides of the roofing work area.

- Determine if mechanical equipment will be used for the work. If so, the warning line must be erected no less than 6 feet from the roof edge parallel to the direction of the mechanical equipment’s operation and no less than 10 feet from the roof edge perpendicular to the direction of the mechanical equipment’s operation.

- If mechanical equipment is not being used, the warning line must be erected no less than 6 feet from the roof edge.

- Employees who are not performing roofing work in the designated work area must remain outside the work area between the roof edge and the warning line.

- Points of access, material-handling areas, storage areas, and hoisting must be connected to the work area by an access path formed by two warning lines. When these areas are not in use, a warning line must be placed across the path at the point where the path intersects the warning line erected around the work area, or the path must be offset in a manner that a person cannot walk directly into the work area.

- All warning lines must be flagged with high-visibility material at no more than 6-feet intervals.

- Warning lines must be rigged and supported so the lowest point (including sag) is no less than 34 inches from the walking/working surface and the highest point is no more than 39 inches from the walking/working surface.

- After being rigged with warning lines, stanchions shall be capable of resisting (without tipping over) a force of at least 16 pounds applied horizontally against the stanchion, 30 inches above the walking/working surface perpendicular to the warning line and in the direction of the floor, roof or platform edge.

- The rope, wire or chain serving as the warning line must have a minimum tensile strength of 500 pounds and, after being attached to the stanchions, must support (without breaking) the load applied to the stanchions.

- Warning lines must be attached to each stanchion in such a way that pulling on one section of the line between stanchions will not result in slack being taken up in the adjacent section before a stanchion tips over.

Rooftop safety is a crucial element in any field, and Presco wants to make sure that you are using the best products available. Give one of our experienced client representatives a call today to see how Presco’s weather hardy, OSHA compliant pennant flagging system can ensure that your business is in compliance.

For more information on Presco products and how we can help keep you safe on the job site, call us at 1-800-527-3295