CAPABILITIES

Presco Controls the Three Drivers of Manufacturing Vinyl Film: Tooling, Process and Formulation

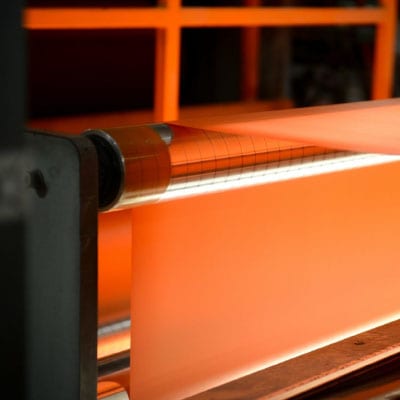

An American-proud company, Presco compounds and extrudes vinyl film in our Sherman, Texas manufacturing facility. Controlling the full process in-house allows Presco to provide customers with highly engineered films which can improve the physical characteristics in products for numerous industries such as military, mining, floor covering and medical. This full process control means we can provide our customers with extruded vinyl film featuring a wide scale of capabilities, whether it be custom formulation, printing, embossing, slitting or extrusion coating, and in gauges ranging from 1.65mil to 26mil and roll widths up to 94″ wide.

PRODUCT CAPABILITIES

ALLOYS

For some products, it might be necessary to improve upon vinyl’s dynamic performance with the addition of another polymer.

SLITTING AND OTHER CONVERTING

Large and small roll diameters are well within our internal slitting capabilities. In-line perforation is available on most formulations. Presco PVC film can be heat sealed to create pocket drapes…

EXTRUSION COATED FILMS

One way to do that was to provide a finished coated composite utilizing our extrusion manufacturing process. The result of that development is Presco’s Extrusion Coated Films.

ENGINEERING CAPABILITIES

CUSTOM FORMULATION

PHTHALATE FREE VINYL